OMEGA-3 AND QUALITY: how can you be sure of selecting a premium plant-based DHA?

Process development and industrial transfer

This Fermentalg newsletter aims to show how we have selected a premium DHA for your dietary or nutraceutical products.

Ethical sourcing of raw materials, clean process and production methods that respect the environment: consumers are increasingly sensitive to these issues.

DEVELOPING A PRODUCTION PROCEDURE

Up-Stream and Down-Stream Processes

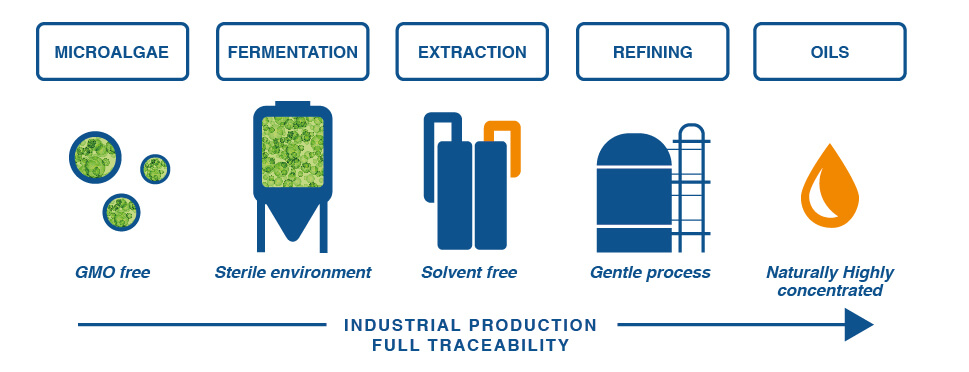

Developing an oil product from a selected high-potential strain of microalgae involves both developing the means of producing lots of algal biomass rich in lipid (the Up-Stream Process or USP), and the means of extracting the lipid and turning it into a high-quality edible oil (the Down-Stream Process or DSP).

The USP takes a small tube of cryopreserved cells and by gradually increasing the volume and providing nutrients allows them to double, and double again, and double again, until there are huge numbers of cells all rich in lipid. The development of these fermentation processes begins in benchtop bioreactors, with volumes from 1 to 5L.

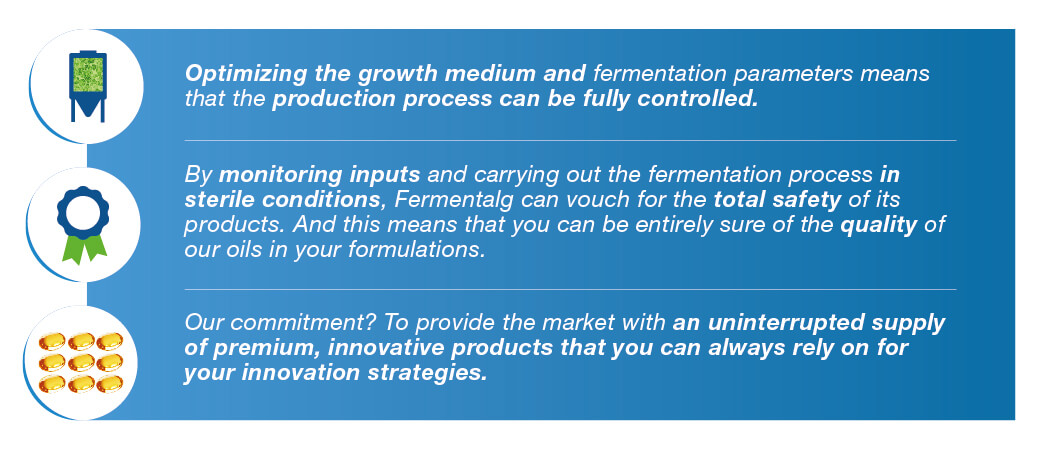

The fermentation[1] process is developed for the purpose of maximizing the productivity of the product, whilst at the same time taking the industrial vision and overall feasibility of the process into account, and is closely linked with the subsequent extraction and purification stages (DSP) since the quality of the biomass can impact the ease with which oils are extracted. This involves optimizing the growth medium in order to meet the cell’s nutritional requirements, along with defining fermentation parameters (pH, oxygen content, temperature, etc.), which together determine the rate at which cells grow and how much oil they produce.

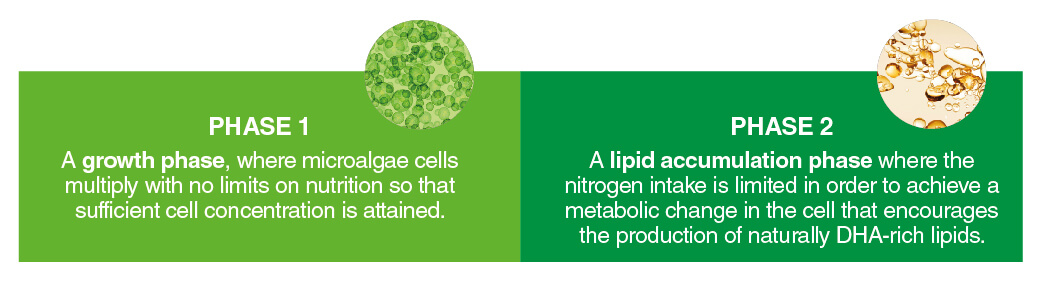

For the procedure developed to produce DHA ORIGINS® 550, the main fermentation is broken down into two phases.

Utmost safety of the growth medium

Extraction and purification

As mentioned above, getting the algae to produce lipid is only the first half of the process. The Down-stream Process (DSP) development is equally critical and can have a huge impact on product quality. Getting the extraction and purification processes right has involved fine-tuning all of the technical operations for separating lipids from the cell biomass and then gently refining the oils. This requires a succession of biomass fractionation procedures each of which can impact another.

Maintaining or improving all of the functional, nutritional and organoleptic qualities of the oils through these lipids extraction and purification[2] procedures is the main challenge alongside maximizing yield and thus reducing waste. Omega-3 fatty acids are precious and fragile compounds that are sensitive to peroxidation, a phenomenon that causes the unpleasant tastes and smells often associated with fish oils. This is why particular care is taken to ensure that the lipids in the oil do not oxidize.

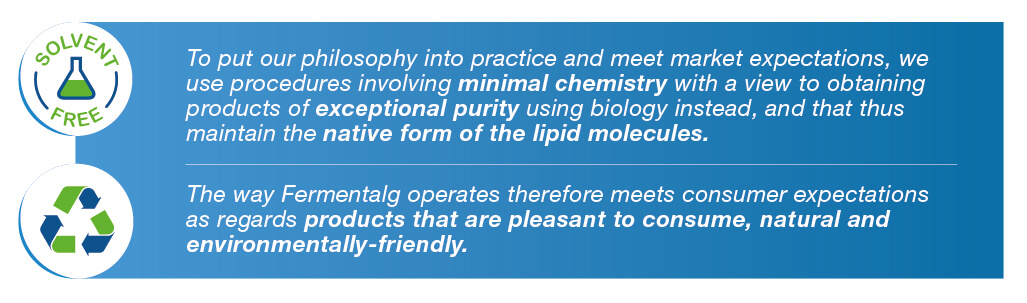

We are also particularly conscious of both the environmental impact of solvent use and the potential impact on the product itself, and have chosen processes that are solvent-free, even though the yields are not as high.

Scale Up to Pilot, and Industrial transfer

Once sufficiently mature, both Up-stream and Down-stream processes are moved to a higher-volume platform so that the performance for industrial production can be validated. Depending on the results obtained, scaling down can be done in order to correct any deviations observed.

Three main activities take place in this pilot unit:

- Further development of fermentation, extraction and purification procedures

- Validation: scale up and production support

- Production of samples

The development activity is an extension of work already carried out at laboratory scale on both USP and DSP. Under the direction of the scientific project experts, teams in the pilot unit carry out and coordinate a set of technical operations to meet the aims of tests. Often these involve testing equipment that is only available at these larger scales or with larger amounts of material, but can range from testing new growth substrates through to the impacts of refining parameters on the colour of our oils.

With a view to eventual industrial transfer or production support, the platform is able to mimic industrial operations so as to be able to validate and predict the performance of the procedure when executed on a large scale and identify technical constraints that may arise as volumes increase.

For producing samples, the platform is organized to meet specific standards relating to the intended use of the samples, so that they are suitable for food use, and the same precautions are taken in protecting the product from, for example, oxidation as would be seen in full production facilities.

The life cycle of products such as the DHA ORIGINS® range goes through three stages:

Each step of the process is designed to optimize the quality of the products we produce and to bring real advantages to our clients. These processes are not distinct, but involve feedback between the various groups involved and continuous improvement to ensure that our best keeps improving.

The nutritional and organoleptic quality of your products

SUPPORT ACTIVITIES

Devevelopment and Production are not carried out in isolation; they fit into a framework that ensures safety, quality and protection of our products and our clients. Fermentalg has several platforms that work hand-in-hand with the scientific and production teams:

An analytical platform

To ensure that our product quality is continuously monitored, a team of trained, experienced engineers and technicians perform analyses throughout all stages of production.

- Systematic measurement of the fatty acid profile, including omega-3 and omega-6 dosage, is performed on crude and refined oils.

- Measurement of indicators of oxidation, microbiology and heavy metal content enables high quality standards to be ensured at each stage of production and packaging.

- Stability studies in real time and accelerated conditions enable the quality of our oils to be monitored and antifcipated over time and their use-by date to be guaranteed.

These analyses are performed in accordance with official, validated techniques and therefore results are guaranteed to be reliable.

Furthermore, the analytical department at Fermentalg also provides the support necessary for for R&D platforms to continue improving processes and products. It participates in an inter-laboratory test scheme that enables performance to be assessed throughout the year.

Regulatory affairs department

Regulatory requirements are complex and differ between countries around the world. This department is responsible for understanding the regulatory environment, and where necessary for obtaining, amending and maintaining the different marketing authorizations for the products in our portfolio.

When new products are being developed, it liaises closely with the R&D teams to ensure that the applicable regulatory requirements have been properly understood and met. It monitors and analyses regulatory changes affecting the product area and passes the information on to the R&D, Marketing, Product and Analysis teams.

The regulatory affairs platform ensures that new products are registered, makes amendments to existing registrations as necessary and helps our client-facing teams to answer any questions received.

Quality department

The quality department at Fermentalg is the final guarantor of the quality of our products. Each batch is validated against our specifications, and against regulatory specifications for products and food safety.

Alongside the regulatory department, the quality department is also responsible for updating our quality specifications in response to changing regulatory and market requirements, and for ensuring that the correct process and procedures are applied throughout the development and production chain.

Fermentalg has a system for managing quality and food safety, which is regularly evaluated during audits for ISO 22000:2018 certification.

Intellectual property unit

Fermentalg respects innovation and in light of this, makes sure that its oils and production processes are free to operate and whenever possible, takes the opportunity to protect its own inventions notably through patents or secret. Fermentalg has a number of patents currently pending for high omega-3 content oils.

IN CONCLUSION

Choosing premium, ethical raw materials to meet the high expectations of consumers

In the omega-3 market more than ever before, plant-based oils from microalgae represent a natural health solution thanks to their naturally high DHA content. They meet high consumer expectations for ethical sourcing, environmental protection and animal welfare.

Produced above ground using gentle, chemical-free extraction processes, they are also part of a clean process approach that respects this exceptional natural product.

Laboratories with lengthy experience in marketing animal-origin omega-3 products can experience difficulties trying to launch and position vegan omega-3 products in their existing omega-3 range. Their concern is that their existing business will have to compete with an alternative offer. However, formulating your products using premium-quality plant-based omega-3 opens up possibilities for:

- offering an alternative to consumers, who are free to choose a product with excellent organoleptic quality and without the smell or aftertaste typical of fish oils

- attracting new customers who are demanding and informed (vegan, concerned about allergens, pollution or other environmental impacts on the product)

- engaging in the social responsibility of stakeholders in the nutraceuticals sector as regards the legacy we leave to future generations. Protecting the environment by choosing ethical sourcing is also preparing for the future!

Is quality more expensive?

Developing a premium raw material requires resources and makes a difference to market prices. However, the price difference of the raw material ultimately has little effect on the daily dose budget.

To arrive at the right decision, a laboratory can reasonably ask itself what the consumer values more. It is product quality and efficacy? It is origin, traceability and safety? Or is it the packaging? Be sure to make the right choices and budget decisions as regards consumer expectations. Plant-based omega-3 meets the demands for sustainability and increasing preferences for vegan and locally-sourced options.

The importance of educating consumers about the quality of the food they eat and how to choose suitable dietary supplements is therefore clear. To explain this approach, brands must justify the added value of their product. Clarity and transparency of information is key to maintaining the trust of the consumer, and it with this in mind that we have shared all that has led up to the DHA ORIGINS® range.

__________

[1] Involves the use of micro-organisms such as microalgae, which are capable of using organic substrates as a source of energy for producing valuable molecules (lipids, proteins, pigments, etc.).

The fermentation process is carried out in bioreactors that enable production to be done under carefully controlled conditions and in large volumes, without taking up large expanses of land.

[2] The set of operations used to process the crude oil by removing impurities in order to obtain an oil with satisfactory organoleptic and chemical qualities.

Initially, high quality algae oils only require slight deodorization and discoloration processes.